Different types of battery systems

A suitable simulation model

BaSiS offers a suitable battery simulation for your system and your challenges. The BaSiS models offered take the special properties and functional principles of different battery systems into account.

Find the solution here that suits you best:

Lithium-ion batteries

Lead-acid batteries

Supercapacitors

Fuel cells/Electrolyzers

Metallic batteries

Use the comprehensive BaSiS solution for your individual user-oriented battery simulation.

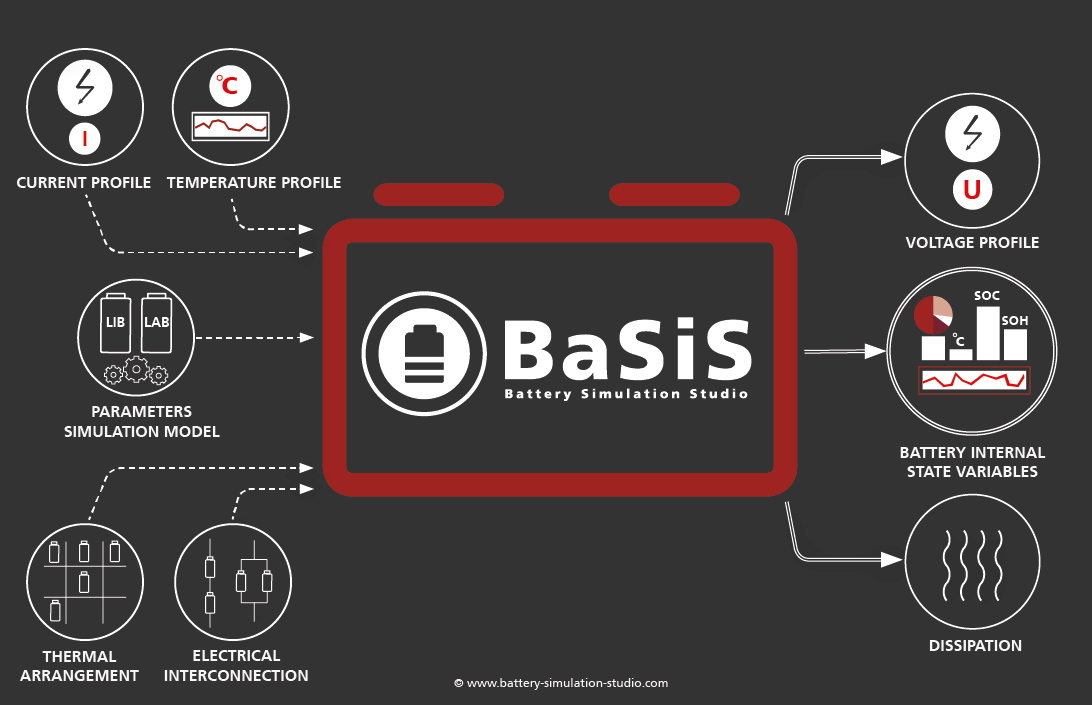

BaSiS is a fast, real-time capable and precise simulation environment for electrochemical storage systems. It shows all dynamic processes and aging effects and supports our customers in making the operation of their storage systems more reliable, robust, durable, and efficient.

As an all-in-one solution, BaSiS provides the necessary software environment and the parameter sets for the simulation of battery systems as well as their internal and external interactions.

Battery simulations by BaSiS can be used directly in your development and test environment, enabling you to improve and accelerate your development cycles while optimizing costs.

BaSiS has been successfully used for years in the development, testing, and optimization of cells, batteries, packs, components and management systems in the field of mobile devices as well as in automotive, plant, and aerospace engineering, including in the simulation of traction batteries.

Advantages

Applications of battery simulators

BaSiS has been successfully used in (inter)national industrial applications for more than 25 years and proves its worth in the sustainable development of robust battery systems on a daily basis.

Battery simulators are used in various areas, such as in the automotive industry, medical engineering, various battery systems in general, as well as sector-specific test benches.

Automotive industry

Battery systems

Medical engineering

Test benches

Optimized product lifecycle

The comprehensive services offered by BaSiS allow you to optimize the development of your battery system throughout the entire product lifecycle.

Three simple steps

Once you have received your individual parameter set and BaSiS, you have all important data and practical tools to obtain meaningful and comprehensive simulation results for your battery.

Do not hesitate to consult our experts for battery simulation and battery emulation!

The Battery Simulation Studio saves you time-consuming measurement series, accelerating development processes of batteries and battery systems.

Additional Services

Advice and parameter determination

More than 15 years of expertise enables us to provide you with comprehensive advice concerning the various modeling approaches, areas of application, and the associated parameterization for your specific application.

Software adaptation

We offer you individual software adaptations to our model to integrate our battery models into your specific simulation or test environment.

Quantification of aging processes

Seminars and workshops

You would like to offer your team qualified advanced training in the simulation and emulation of batteries and their use in real practical applications? Get in touch with us and we will customize the seminar to your desired subject areas, your team’s previous knowledge and your goals.

This is how battery simulation works

What is battery simulation?

Battery simulation is used to model a battery’s electrical behavior in a virtual environment. This makes it possible to study the battery performance without requiring a real battery. The simulation allows for predicting a battery’s behavior under different conditions, contributing to improving the battery’s design and extending its life.

How is the optimum battery simulation developed?

To enable optimum modeling of a system in the battery simulation, the appropriate modeling approach and the acceptable model simplifications need to be selected. In this process, optimum alignment to the requirements of the specific objective and the respective system is crucial. In addition, cost-benefit considerations may also play a role.

After choosing the appropriate approach, the challenges in developing the optimum battery simulator are model development, testing, implementation and parameterization.

What does a battery simulation model comprise?

- Equations or systems of equations

- Input parameters (e.g. current and ambient temperature) and output parameters (e.g. voltage) that are calculated based on the underlying equations and the current state of the battery (e.g. SOC)

- Parameters that differ for the specific batteries – parameters can be provided in the form of characteristics to update them during the battery simulation, for example according to temperature, or the physical processes are depicted

Contact

Dipl.-Ing. Philipp Brosche

Hardware-in-the-Loop Systems

Contact form

Send us a message and we will contact you as soon as possible.